Views: 5 Author: Site Editor Publish Time: 2024-06-17 Origin: Site

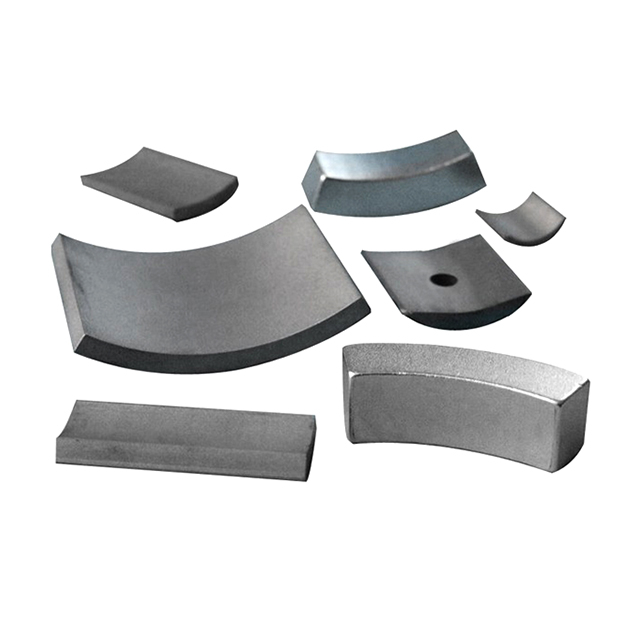

In the world of advanced materials, SmCo magnets stand out for their exceptional magnetic properties and widespread applicability in modern technologies. As a leading magnets manufacturer, Honesun specializes in the production of high-quality SmCo (Samarium Cobalt) magnets, which are renowned for their performance in extreme conditions. This comprehensive guide explores the characteristics, manufacturing process, applications, and benefits of SmCo magnets.

SmCo magnets, made from an alloy of samarium and cobalt, belong to the family of rare earth permanent magnets. They were developed in the early 1970s and are known for their impressive magnetic strength and remarkable thermal stability. SmCo magnets typically come in two series: SmCo5 and Sm2Co17, and are characterized by their high coercivity, moderate temperature coefficient, and excellent corrosion resistance.

Magnetic Strength: SmCo magnets have a maximum energy product (BH max) ranging from 16 MGOe to 32 MGOe, making them highly effective in applications requiring strong permanent magnets.

Temperature Tolerance: One of the defining features of SmCo magnets is their ability to perform under high temperatures. They can withstand temperatures up to 350 degrees Celsius without a significant loss in magnetic performance.

Corrosion Resistance: Unlike many other magnets, SmCo magnets exhibit excellent resistance to corrosion and oxidation, which eliminates the need for additional surface treatments in most applications.

Coercivity: SmCo magnets are known for their high coercivity (resistance to demagnetization), typically above 10 kOe, which makes them ideal for applications involving high demagnetizing fields.

The production of SmCo magnets at Honesun, a premier magnets manufacturer, involves several critical steps:

Raw Material Preparation: The process begins with the precise weighing and blending of samarium oxide and cobalt, along with iron and copper additives. The mixture is then melted in an induction melting furnace to create the SmCo alloy.

Milling and Powder Preparation: Once the alloy is formed, it is crushed into a fine powder. This powder is then jet milled to achieve a particle size of less than 10 microns, which is crucial for the magnetic performance of the final product.

Pressing: The fine powder is compacted under high pressure in a magnetic field to align the particles and form a magnet in the desired shape. This alignment is essential as it significantly enhances the magnet's anisotropy and magnetic properties.

Sintering: After pressing, the compacted magnet undergoes sintering at temperatures between 1100°C and 1200°C. This step densifies the magnet and enhances its mechanical strength.

Heat Treatment: Post-sintering, the magnets are subjected to a series of heat treatments, which optimize their magnetic properties. This includes tempering at temperatures up to 800°C to achieve the desired magnetic characteristics.

Finishing: The magnets are then ground to precise dimensions and surface finished. Tolerances of +/-0.05 mm are common in the dimensions of finished magnets.

SmCo magnets are used in a variety of high-tech and industrial applications, including:

Aerospace and Defense: Their high-temperature stability makes them suitable for use in aerospace applications, where performance under extreme conditions is crucial.

Electric Motors and Generators: SmCo magnets are commonly used in the manufacture of high-performance motors and generators due to their ability to maintain high magnetic output over a wide temperature range.

Medical Devices: Their stability and biocompatibility make them ideal for use in certain medical implants and magnetic resonance imaging (MRI) machines.

Sensors and Actuators: The precise performance of SmCo magnets under varying environmental conditions makes them ideal for sensors and actuators in automotive and industrial applications.

Choosing Honesun as your SmCo magnets manufacturer offers numerous advantages. With state-of-the-art manufacturing facilities and a commitment to quality, Honesun ensures that each magnet not only meets but exceeds industry standards. Our SmCo magnets are recognized for their superior quality, consistent performance, and durability. Furthermore, Honesun’s expertise in advanced material science allows us to provide customized solutions tailored to meet specific application needs of our clients.

SmCo magnets are essential components in many modern applications, providing high magnetic strength, exceptional thermal stability, and excellent corrosion resistance.Honesun continues to innovate and provide top-quality SmCo magnets that are integral to the advancements in technology and industry. Whether you are developing products for the aerospace sector, automotive industry, or medical technologies, Honesun’s SmCo magnets offer the reliability and performance necessary to drive success.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.