| Availability: | |

|---|---|

| Quantity: | |

| Product Name | 10mm x 2mm neodymium magnets |

| Material | Neodymium (Nd), Iron (Fe), and Boron (B) |

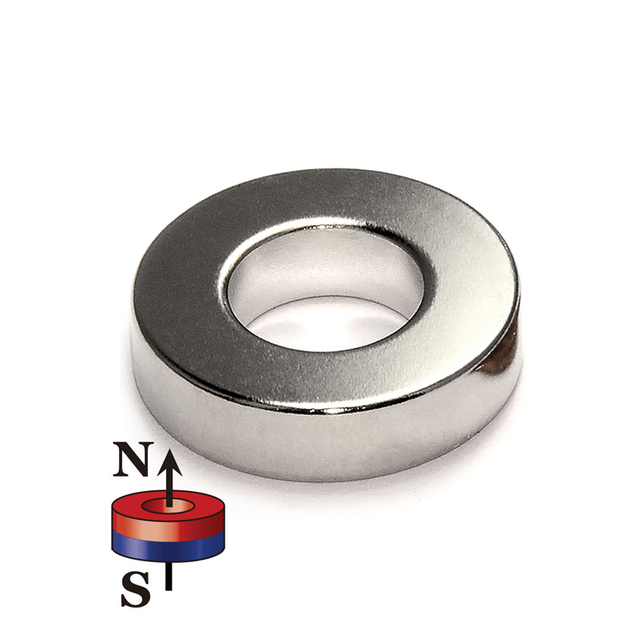

| Size | Customized size |

| Shape | Customized (block,Disc,Cylinder, Bar, Ring,Arc,Countersunk, Segment, hook) |

| Coating | Customised (Ni, Zn, Epoxy, Gold, etc.) |

| Size tolerance | ±0.06mm for diamater / thickness, ±0.1mm for width / length |

| Density | 6.1-8.6g/cm³ |

| Magnetization | Thickness Magnetized, Axially Magnetized, Diametrally Magnetized |

| Applications | Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors,microphones, wind turbines, wind generators,printer, switchboard, packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect. |

1.What role do 10mm x 2mm neodymium magnets play in magnetic levitation technology?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are used in magnetic levitation technology to create a strong magnetic field that can suspend an object in mid-air. The magnets are arranged in a specific pattern to create a stable magnetic field that can support the weight of the object. The magnets are also used to control the movement of the object, allowing it to move in a specific direction or remain stationary.

2.About the scale of 10mm x 2mm neodymium magnets factory

Neodymium magnets are produced in a variety of sizes, shapes, and grades. The size of a neodymium magnet factory can vary greatly depending on the type of magnets being produced. Some factories may only produce small magnets, while others may produce large magnets for industrial applications. The size of the factory also depends on the number of employees and the amount of equipment needed to produce the magnets.

3.Are there any ethical concerns regarding the use of 10mm x 2mm neodymium magnets?

Yes, there are ethical concerns regarding the use of Neodymium Magnets. Neodymium magnets are powerful and can cause serious injury if swallowed. They can also interfere with medical devices such as pacemakers and defibrillators. Additionally, Neodymium magnets can be dangerous if used in the wrong way, such as when used to create a powerful magnetic field. Finally, Neodymium magnets can be hazardous to the environment if not disposed of properly.

4.Are 10mm x 2mm neodymium magnets used in electric vehicles?

Yes, neodymium magnets are used in electric vehicles. They are used in the electric motors that power the vehicle, as well as in the batteries that store the energy. Neodymium magnets are also used in the regenerative braking systems of electric vehicles, which help to capture and store energy that would otherwise be lost as heat.

5.What is the manufacturing process for 10mm x 2mm neodymium magnets?

Our 10mm x 2mm neodymium magnets products undergo strict quality control to ensure customer satisfaction. 1. Raw Material Preparation: Neodymium magnets are made from an alloy of neodymium, iron, and boron. The raw materials are melted together in a vacuum induction furnace to create a homogenous alloy. 2. Compacting: The molten alloy is then poured into a die and compacted under high pressure to form a solid block. 3. Sintering: The compacted block is then heated in a vacuum furnace to sinter the material, which increases its strength and magnetic properties. 4. Machining: The sintered block is then machined into the desired shape and size. 5. Magnetizing: The machined magnet is then magnetized by exposing it to a strong magnetic field. This process aligns the magnetic domains within the material, creating a permanent magnet.

6.How have 10mm x 2mm neodymium magnets revolutionized the manufacturing industry?

Neodymium magnets have revolutionized the manufacturing industry by providing a powerful, lightweight, and cost-effective alternative to traditional ferrite magnets. Neodymium magnets are used in a variety of applications, from motors and generators to sensors and medical equipment. They are also used in the production of consumer electronics, automotive components, and industrial machinery. Neodymium magnets are more powerful than ferrite magnets, allowing for smaller, lighter, and more efficient designs. They are also more cost-effective, making them a popular choice for manufacturers.

7.Can 10mm x 2mm neodymium magnets damage credit cards or electronic devices?

Being one of the top 10mm x 2mm neodymium magnets manufacturers in China, We attach great importance to this detail. No, neodymium magnets will not damage credit cards or electronic devices. However, it is important to keep in mind that neodymium magnets are very powerful and can cause damage to other magnetic materials, such as hard drives, speakers, and other electronic components. Therefore, it is important to keep neodymium magnets away from any electronic devices.

8.How do 10mm x 2mm neodymium magnets contribute to renewable energy storage?

Neodymium magnets are used in a variety of renewable energy storage systems, such as flywheels, supercapacitors, and batteries. Flywheels use the magnets to store energy in the form of kinetic energy, while supercapacitors use them to store energy in the form of electrical charge. Batteries use the magnets to store energy in the form of chemical energy. Neodymium magnets are also used in electric motors and generators, which are essential components of renewable energy systems.

9.Are 10mm x 2mm neodymium magnets affected by extreme temperatures?

Yes, neodymium magnets can be affected by extreme temperatures. They can become brittle and crack if exposed to temperatures above 175°C (347°F). They can also lose their magnetism if exposed to temperatures below -45°C (-49°F).

10.What are the pros and cons of using 10mm x 2mm neodymium magnets?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Pros: - Neodymium magnets are extremely strong and can hold a large amount of weight. - They are very versatile and can be used in a variety of applications. - They are relatively inexpensive and easy to find. - They are corrosion-resistant and can withstand extreme temperatures. Cons: - Neodymium magnets are brittle and can easily break if dropped or mishandled. - They can be dangerous if swallowed, as they can cause serious internal damage. - They can be difficult to work with due to their strength. - They can be expensive depending on the size and grade of the magnet.

11.How are 10mm x 2mm neodymium magnets made?

Our products & services cover a wide range of areas and meet the needs of different fields. Neodymium magnets are made by a process called powder metallurgy. This process involves mixing neodymium, iron, and boron powder together and then compressing the mixture into a mold. The mold is then heated to a very high temperature, which causes the particles to bond together and form a solid magnet.

12.Can 10mm x 2mm neodymium magnets be used in underwater applications?

Our mission is to provide customers with the best solutions for 10mm x 2mm neodymium magnets. Yes, neodymium magnets can be used in underwater applications. However, they must be coated with a protective material such as nickel or epoxy to prevent corrosion.

13.How do 10mm x 2mm neodymium magnets affect electronic devices?

Being one of the top 10mm x 2mm neodymium magnets manufacturers in China, We attach great importance to this detail. Neodymium magnets can affect electronic devices in a variety of ways. They can cause interference with the operation of the device, as the magnetic field can interfere with the operation of the device's internal components. They can also cause physical damage to the device, as the strong magnetic field can cause components to become magnetized and attract each other, potentially damaging the device. Finally, they can cause data loss, as the strong magnetic field can cause data stored on magnetic media to become corrupted or erased.

14.Can 10mm x 2mm neodymium magnets be shaped to fit specific applications?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, neodymium magnets can be shaped to fit specific applications. They can be cut, drilled, and machined into various shapes and sizes.

15.About 10mm x 2mm neodymium magnets delivery date

Neodymium magnets are usually shipped within 1-2 business days of ordering. Depending on the size and quantity of the magnets, delivery times may vary.

| Product Name | 10mm x 2mm neodymium magnets |

| Material | Neodymium (Nd), Iron (Fe), and Boron (B) |

| Size | Customized size |

| Shape | Customized (block,Disc,Cylinder, Bar, Ring,Arc,Countersunk, Segment, hook) |

| Coating | Customised (Ni, Zn, Epoxy, Gold, etc.) |

| Size tolerance | ±0.06mm for diamater / thickness, ±0.1mm for width / length |

| Density | 6.1-8.6g/cm³ |

| Magnetization | Thickness Magnetized, Axially Magnetized, Diametrally Magnetized |

| Applications | Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors,microphones, wind turbines, wind generators,printer, switchboard, packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect. |

1.What role do 10mm x 2mm neodymium magnets play in magnetic levitation technology?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are used in magnetic levitation technology to create a strong magnetic field that can suspend an object in mid-air. The magnets are arranged in a specific pattern to create a stable magnetic field that can support the weight of the object. The magnets are also used to control the movement of the object, allowing it to move in a specific direction or remain stationary.

2.About the scale of 10mm x 2mm neodymium magnets factory

Neodymium magnets are produced in a variety of sizes, shapes, and grades. The size of a neodymium magnet factory can vary greatly depending on the type of magnets being produced. Some factories may only produce small magnets, while others may produce large magnets for industrial applications. The size of the factory also depends on the number of employees and the amount of equipment needed to produce the magnets.

3.Are there any ethical concerns regarding the use of 10mm x 2mm neodymium magnets?

Yes, there are ethical concerns regarding the use of Neodymium Magnets. Neodymium magnets are powerful and can cause serious injury if swallowed. They can also interfere with medical devices such as pacemakers and defibrillators. Additionally, Neodymium magnets can be dangerous if used in the wrong way, such as when used to create a powerful magnetic field. Finally, Neodymium magnets can be hazardous to the environment if not disposed of properly.

4.Are 10mm x 2mm neodymium magnets used in electric vehicles?

Yes, neodymium magnets are used in electric vehicles. They are used in the electric motors that power the vehicle, as well as in the batteries that store the energy. Neodymium magnets are also used in the regenerative braking systems of electric vehicles, which help to capture and store energy that would otherwise be lost as heat.

5.What is the manufacturing process for 10mm x 2mm neodymium magnets?

Our 10mm x 2mm neodymium magnets products undergo strict quality control to ensure customer satisfaction. 1. Raw Material Preparation: Neodymium magnets are made from an alloy of neodymium, iron, and boron. The raw materials are melted together in a vacuum induction furnace to create a homogenous alloy. 2. Compacting: The molten alloy is then poured into a die and compacted under high pressure to form a solid block. 3. Sintering: The compacted block is then heated in a vacuum furnace to sinter the material, which increases its strength and magnetic properties. 4. Machining: The sintered block is then machined into the desired shape and size. 5. Magnetizing: The machined magnet is then magnetized by exposing it to a strong magnetic field. This process aligns the magnetic domains within the material, creating a permanent magnet.

6.How have 10mm x 2mm neodymium magnets revolutionized the manufacturing industry?

Neodymium magnets have revolutionized the manufacturing industry by providing a powerful, lightweight, and cost-effective alternative to traditional ferrite magnets. Neodymium magnets are used in a variety of applications, from motors and generators to sensors and medical equipment. They are also used in the production of consumer electronics, automotive components, and industrial machinery. Neodymium magnets are more powerful than ferrite magnets, allowing for smaller, lighter, and more efficient designs. They are also more cost-effective, making them a popular choice for manufacturers.

7.Can 10mm x 2mm neodymium magnets damage credit cards or electronic devices?

Being one of the top 10mm x 2mm neodymium magnets manufacturers in China, We attach great importance to this detail. No, neodymium magnets will not damage credit cards or electronic devices. However, it is important to keep in mind that neodymium magnets are very powerful and can cause damage to other magnetic materials, such as hard drives, speakers, and other electronic components. Therefore, it is important to keep neodymium magnets away from any electronic devices.

8.How do 10mm x 2mm neodymium magnets contribute to renewable energy storage?

Neodymium magnets are used in a variety of renewable energy storage systems, such as flywheels, supercapacitors, and batteries. Flywheels use the magnets to store energy in the form of kinetic energy, while supercapacitors use them to store energy in the form of electrical charge. Batteries use the magnets to store energy in the form of chemical energy. Neodymium magnets are also used in electric motors and generators, which are essential components of renewable energy systems.

9.Are 10mm x 2mm neodymium magnets affected by extreme temperatures?

Yes, neodymium magnets can be affected by extreme temperatures. They can become brittle and crack if exposed to temperatures above 175°C (347°F). They can also lose their magnetism if exposed to temperatures below -45°C (-49°F).

10.What are the pros and cons of using 10mm x 2mm neodymium magnets?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Pros: - Neodymium magnets are extremely strong and can hold a large amount of weight. - They are very versatile and can be used in a variety of applications. - They are relatively inexpensive and easy to find. - They are corrosion-resistant and can withstand extreme temperatures. Cons: - Neodymium magnets are brittle and can easily break if dropped or mishandled. - They can be dangerous if swallowed, as they can cause serious internal damage. - They can be difficult to work with due to their strength. - They can be expensive depending on the size and grade of the magnet.

11.How are 10mm x 2mm neodymium magnets made?

Our products & services cover a wide range of areas and meet the needs of different fields. Neodymium magnets are made by a process called powder metallurgy. This process involves mixing neodymium, iron, and boron powder together and then compressing the mixture into a mold. The mold is then heated to a very high temperature, which causes the particles to bond together and form a solid magnet.

12.Can 10mm x 2mm neodymium magnets be used in underwater applications?

Our mission is to provide customers with the best solutions for 10mm x 2mm neodymium magnets. Yes, neodymium magnets can be used in underwater applications. However, they must be coated with a protective material such as nickel or epoxy to prevent corrosion.

13.How do 10mm x 2mm neodymium magnets affect electronic devices?

Being one of the top 10mm x 2mm neodymium magnets manufacturers in China, We attach great importance to this detail. Neodymium magnets can affect electronic devices in a variety of ways. They can cause interference with the operation of the device, as the magnetic field can interfere with the operation of the device's internal components. They can also cause physical damage to the device, as the strong magnetic field can cause components to become magnetized and attract each other, potentially damaging the device. Finally, they can cause data loss, as the strong magnetic field can cause data stored on magnetic media to become corrupted or erased.

14.Can 10mm x 2mm neodymium magnets be shaped to fit specific applications?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, neodymium magnets can be shaped to fit specific applications. They can be cut, drilled, and machined into various shapes and sizes.

15.About 10mm x 2mm neodymium magnets delivery date

Neodymium magnets are usually shipped within 1-2 business days of ordering. Depending on the size and quantity of the magnets, delivery times may vary.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.