Views: 4 Author: Site Editor Publish Time: 2024-03-28 Origin: Site

Flexible magnet, also known as rubber magnet, is a type of magnet that is made from a flexible rubber material that has been magnetized. It is commonly used in various industries and applications due to its flexibility and magnetic properties.

Here are some key things you need to know about flexible magnets:

1. Composition and Production: Flexible magnets are made from a combination of ferrite powder and rubber material, which are mixed together and then subjected to a manufacturing process known as extrusion. This process involves shaping the mixture into a thin sheet or strip, which is then magnetized to make it magnetic.

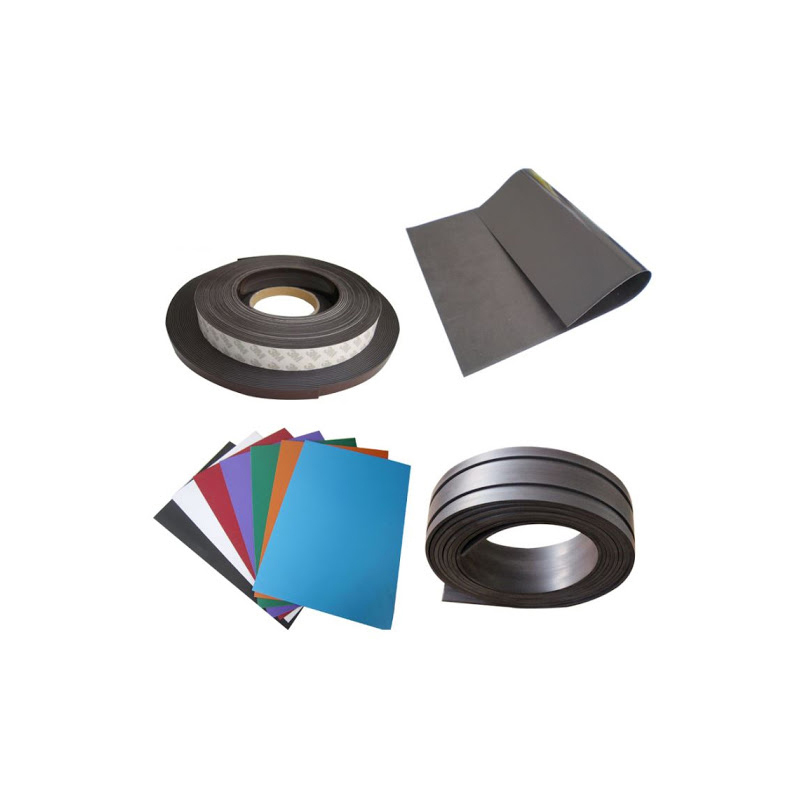

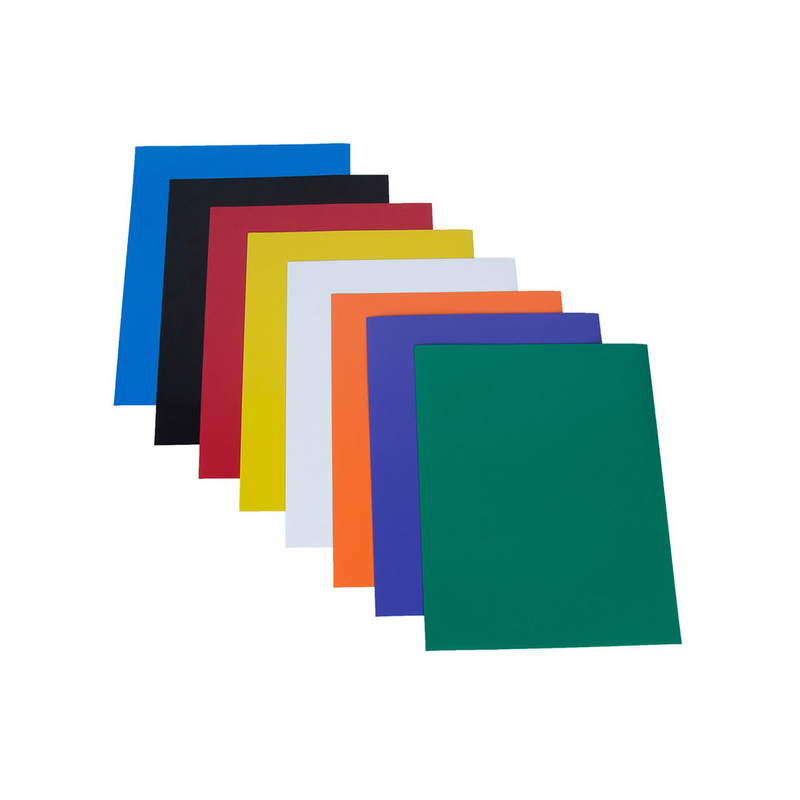

2. Types: Flexible magnets come in various types such as plain magnets, one-side laminated magnets, and double-side laminated magnets. The laminated magnets are often used for print applications, as they provide a smooth, printable surface, while plain magnets are commonly used for signage and labeling purposes.

3. Different Shapes and Sizes: Flexible magnets are available in different shapes and sizes, including sheets, strips, rolls, and custom shapes. This allows for versatility in their usage and makes them suitable for various applications.

4. Advantages: Flexible magnets have several advantages over other types of magnets. They are lightweight, flexible, and easy to cut, bend, and shape. This makes them ideal for applications where other types of magnets may not be suitable. They are also cost-effective and can be produced in large quantities at a relatively low cost.

5. Applications: Flexible magnets have a wide range of applications in different industries. They are commonly used in advertising, for making signs, banners, and displays. They are also used in the automotive industry for various purposes such as holding parts in place and sealing doors. In the home, they are used for refrigerator magnets, magnetic toys, and closures for cabinets and drawers.

6. Magnetic Strength: The strength of a flexible magnet depends on the type and thickness of the material used. Generally, flexible magnets have a lower magnetic strength compared to other types of magnets, such as neodymium magnets. However, they are strong enough for most applications in which they are used.

7. Resistance to Demagnetization: Flexible magnets are susceptible to demagnetization over time due to exposure to high temperatures or strong external magnetic fields. However, proper handling and storage can help prolong their magnetic strength.

8. Care and Maintenance: Flexible magnets require minimal maintenance. They should be kept away from extreme temperatures and strong magnetic fields to prevent demagnetization. They can be cleaned with a damp cloth and mild detergent, but strong chemicals or abrasive materials should be avoided.

9. Environmental Impact: Flexible magnets are considered environmentally friendly as they do not contain any hazardous materials. They can be recycled and reused, making them a sustainable choice.

10. Safety Considerations: Flexible magnets are generally safe to handle, but caution should be taken when working with them. They can pose a choking hazard to children and should be kept away from small children. They should also be kept away from sensitive electronic devices as they can interfere with their functioning.

flexible magnets are versatile, cost-effective, and have a wide range of applications. They are suitable for a variety of industries and can be easily handled and maintained. With proper care, they can provide long-lasting magnetic strength and are a sustainable choice for various applications.

Organize your work or home space with our Flexible Magnets. These pliable and strong magnets are perfect for labeling items, holding up important papers, or creating a convenient magnetic calendar. With their ability to stick to any metallic surface, you can keep everything in place and easily move things around as needed. Get your hands on our Flexible Magnets and experience hassle-free organization.

Here are some frequently asked questions about Silicone Glass Lids :

1. Can flexible magnets be recycled?

Yes, flexible magnets can be recycled. However, they need to be separated from other materials, as they may interfere with the recycling process. Contact your local recycling center to find out how to properly recycle flexible magnets.

2. Are flexible magnets easy to remove once applied?

Flexible magnets can be easily removed as they do not have a strong adhesive like traditional rigid magnets. However, they may leave some residue or lose their shape if not removed carefully.

3. Can flexible magnets be used for sensitive surfaces?

Flexible magnets can be used on most smooth surfaces without causing any damage or leaving marks. However, they may leave some residue if used on delicate or porous surfaces.

4. How can I attach a flexible magnet to a non-magnetic surface?

Flexible magnets can be used to create a magnetic latch, or they can be attached to a non-magnetic surface using an adhesive backing. Some manufacturers also offer pre-cut self-adhesive discs specifically for this purpose.

5. What is the maximum temperature that flexible magnets can withstand?

The maximum operating temperature for flexible magnets varies depending on the material and composition. Generally, they can withstand temperatures up to 200-300℃, but it is best to check with the manufacturer for specific temperature limits.

6. Can flexible magnets be used for heavy-duty applications?

Flexible magnets are not as strong as traditional rigid magnets and are not suitable for heavy-duty applications. However, they can be combined with a more powerful magnet for increased holding strength.

7. How can I test the strength of a flexible magnet?

The strength of a flexible magnet can be tested by using a Gauss meter, which measures the magnetic field strength. Another simple way is to see how many metal objects the magnet can hold up without falling or sliding.

8. Can flexible magnets be cut with regular scissors?

Most flexible magnets can be easily cut with sharp scissors or a utility knife. However, for thicker or stronger magnets, a heavy-duty cutting tool may be necessary.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.